A double barrel timepiece with retrograde functions and perpetual calendar on the retrogrades is quite a complication. In mechanical terms this complication combination on a timepiece only 40 years ago would have taken the finest Master Watchmakers all trapped in a little room separate from the normal factory years to accomplish, by hand. Each piece cut by hand on the micro Watchmaking lathes we use on a “per piece” basis. Today thanks to computer aided design and computer aided spark erosion techniques for cutting parts not visible to the human eye we can all enjoy pieces of this kind and execution. Of course this is still at a high price tag due to the Watchmakers still having to put together the entire movement by hand. Tweaking and testing each and every part as it’s built up to work in symbiotic harmony. I present you a repair on another of the worlds most complicated timepieces. The Leviev Double Barille’.

As you all know that follow me I have most of my expertise from yesteryear in Chronographs. I always had a passion for pre 1970’s Chrono’s. Probably due to opening one certain old Vacheron Constantin as a child. This is my favorite brand by the way. I used to sit and file the flyback hammers, polish the faces of them and tweak them for just the right amount play on the minute wheel for days to get one running super accurate on return. The meshing of the intermediate wheel, the driving wheels depth with its sister wheel, the epicycloidal shaping of certain manufacturers execution of teeth… . . sorry I got carried away there reminiscing when Chrono’s were almost all made by hand and the parts were made to last centuries. My second passion in Watchmaking is Retrogrades of all kinds. I love to work on these complicated intricate micro miniature mechanisms.

A Retrograde date feature has two basic mechanical executions. In the past all of them were made by hand and the flyback functions tied to an actual piece of a balance wheel hairspring. This was a labor of love to make by Watchmakers. If any of you knew the time it takes for a Watchmaker to try and get one of these mechanisms to flyback and “zero” consecutively time after time without a hiccup you would probably understand the cost of an older Swiss mechanism.

The more recent designs of these Retrograde mechanisms are all gears, heart cams and have no hairsprings. This of course gives us a more stable platform and less mechanical returns to the bench. The wonders of computer design come into play once again. In addition to the Retrograde flyback of the date on this piece we have it tied to a Perpetual Calendar mechanism. This keeps the Perpetual flying at February 28th and / or the 30th or 31st of any month right on time. Don’t think a Perpetual Calendar is a small feat to accomplish either. Most Perpetual’s take a special Watchmaker in Switzerland that learns each mechanism over perhaps a years time to work on them for repairs. You can’t just open any brand and have a go at it !

At this level of Watchmaking this is how most of our complications do in fact get proper service. Each brand trains a few select Master Watchmakers on one particular complicated timepieces complications, over one or two years time, to learn all its idiosyncrasies in his/her sleep. All of these timepieces from the entire planet earth that are in need of repair must go back to Switzerland to this one watchmaker for repair. No parts or specialized tools needed for the particular piece are allowed outside of this Watchmakers bench and the safe in the complicated room. This ensures proper repair at this insane level of micro mechanics.

This Double Barrel watch also has a Reserve De Marche indicator for the rundown of the mainspring. It’s a fuel gauge for the watch. If it gets low wear it or wind it.

The Double Barrels are the key to making a very stable timekeeper. I most prefer watches with at least two barrels. Common consumers of fine luxury watches don’t understand the real reason behind more than one barrel. They think that it is strictly so they do not have to wind the piece if they don’t wear it over the weekend and pick up their “beater” for boating or racquetball. Yes, two or more barrels will give you considerably more time between winds or wear. The real reason is that it creates an imaginary long mainspring. If you envision one veeeeerrrry long mainspring now in your minds eye you begin to understand the mechanical aspects it can have. It gives us constant power at a more constant force for longer periods of time. This makes the timing of the entire piece rock solid for longer periods and at a “more stable length of time” at the “same” timing numbers. More accuracy over time, basically. Like a tank. Gotta’ love it. There is a differential between the barrels, for all you car repair people to get a grasp on the mechanical interaction between barrels. Not a simple mechanical accomplishment to implement two or more barrels in a watch. Four barrels like the Chopard Quattro is extremely complicated to repair just the barrels.

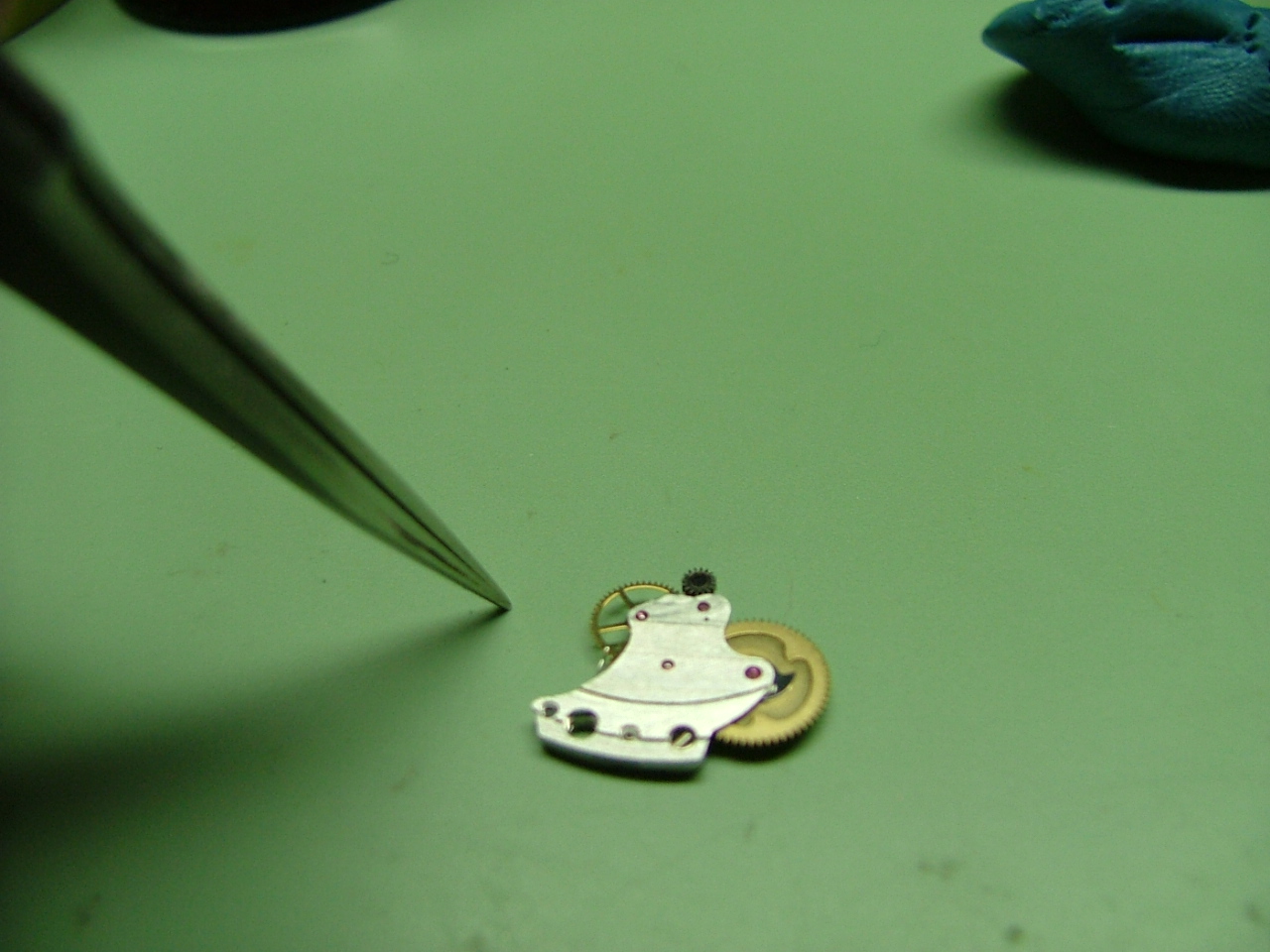

This watch had some automatic problems. Some broken pivots, wig wag pinion offsets, jewel adjustments and more. If you have a look at some of the pictures I have snapped a few of just the automatic system for you to see. Also have a look at the wonderful automatic rotor execution. It’s jeweled in a very pleasing way.

This timepiece was dropped, so the balance pivots had to be placed on the Jacot Lathe for hand polishing and reforming of pivot straightness. I have this killer Jacot that is over 100 years old and just simply beautiful to look at. It’s actually German in manufacture. A Jacot Lathe is not electric and is used with a violin type bow for movement. If you were always wondering why we don’t turn on the electricity and join the revolution, I’ll explain. The thickness of a balance wheel pivot is barely visible to humans. If we as Watchmakers have to polish it because it was scored by a broken or dry jewel, watch dropped mushrooming the pivot, or a thousand other reasons, it must be done slowly. If it’s “turned” to fast as we polish and reshape the pivot it will BURN the metal. Meaning, it will harden the metal to a strength we do not want. Annealing is the proper term. So back to the freakin’ stone ages we go with bow with a horse hair in hand and some burnishing sticks with Diamontine paste of all degrees. A Watchmaker must have patience … A Watchmaker must have … A Watchmaker must .. .

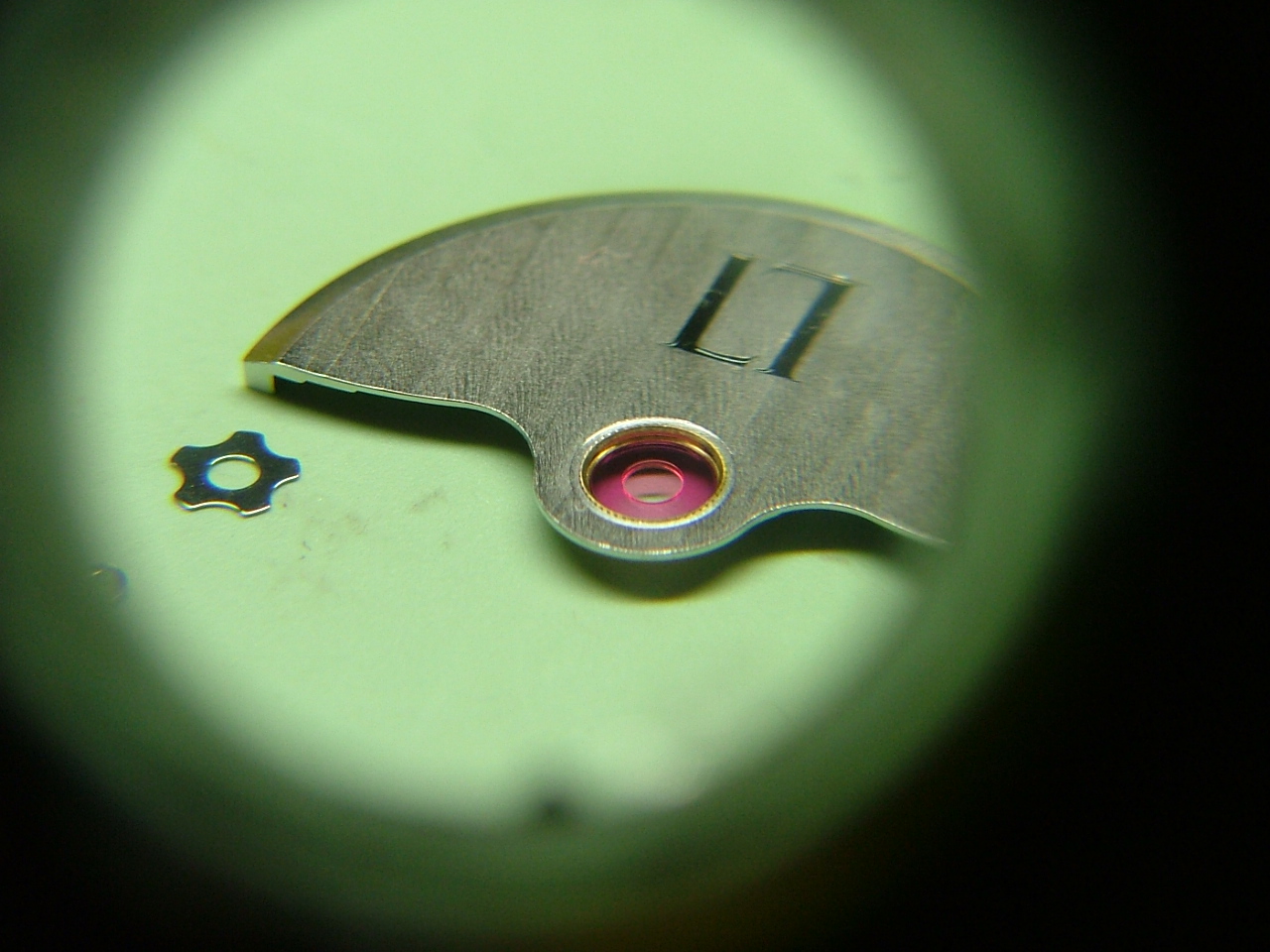

The escapement needed some work as well. It seems the pallet fork jewels had moved when the movement jammed. Under fiber optic microscope inspection the jewels were repaired and adjusted using a special pallet fork jewel micrometer adjusting depthing tool that heats the shellac as well to proper temperature per manufacturers requirements.

There were also many other problems in this piece like bent wheels we won’t get into.

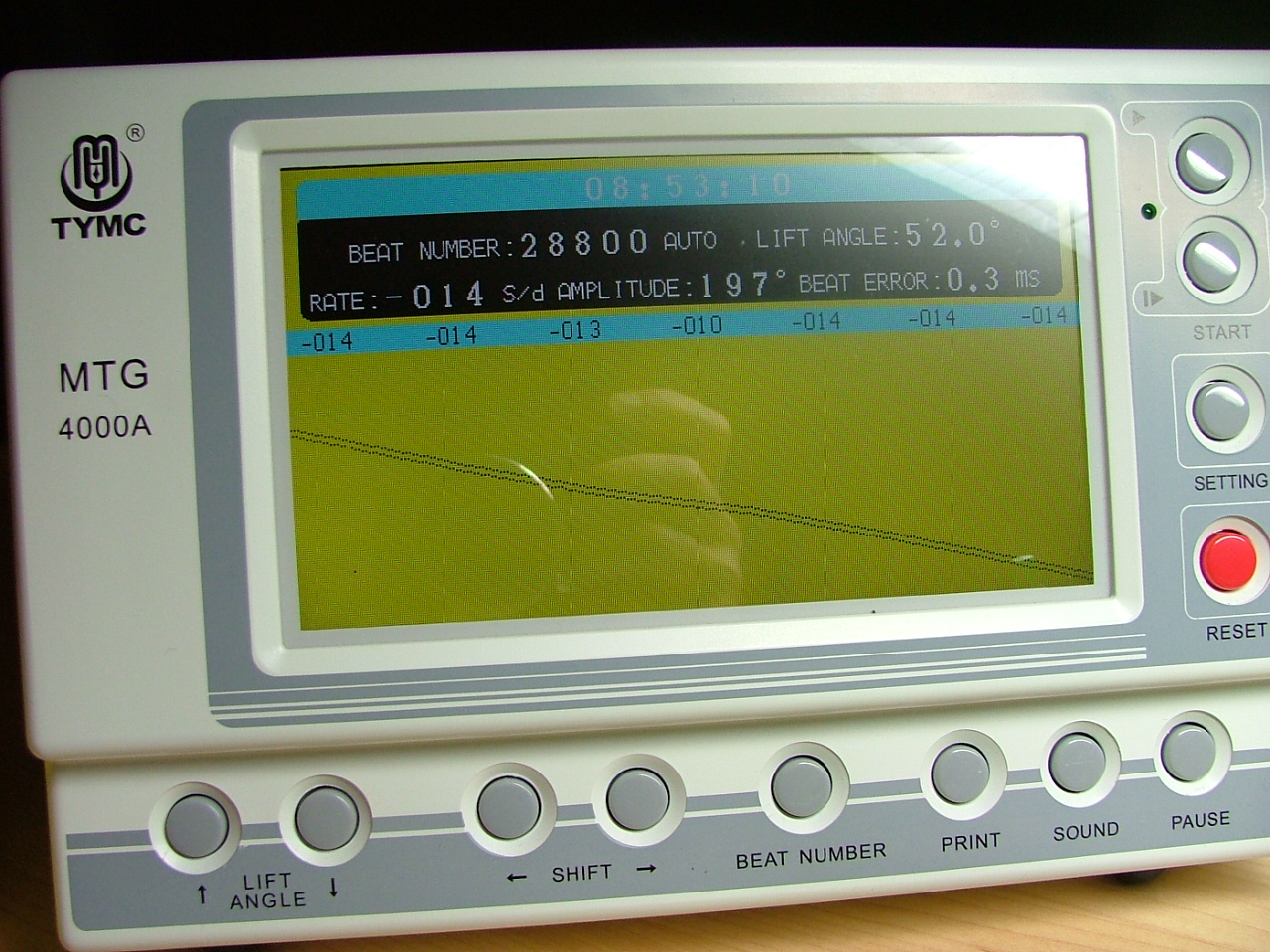

I had to execute all repairs while carefully not destroying any of the wonderfully polished dial pieces, diamonds inset around perimeters and of course all the plates and bridges that are adorned with high grade finishing. It is basically a “Skeleton” watch you know. As you can see from the computerized timing machine picture is came in loosing a considerable amount of time per position. I love this timing machine by the way. A review will be coming.

I hope you all enjoyed another look inside a crazy expensive and complicated mechanical watch from the Dan Spitz Watchmaker bench, both here in the USA and in Switzerland, that is normally not available. Thrash Metal!