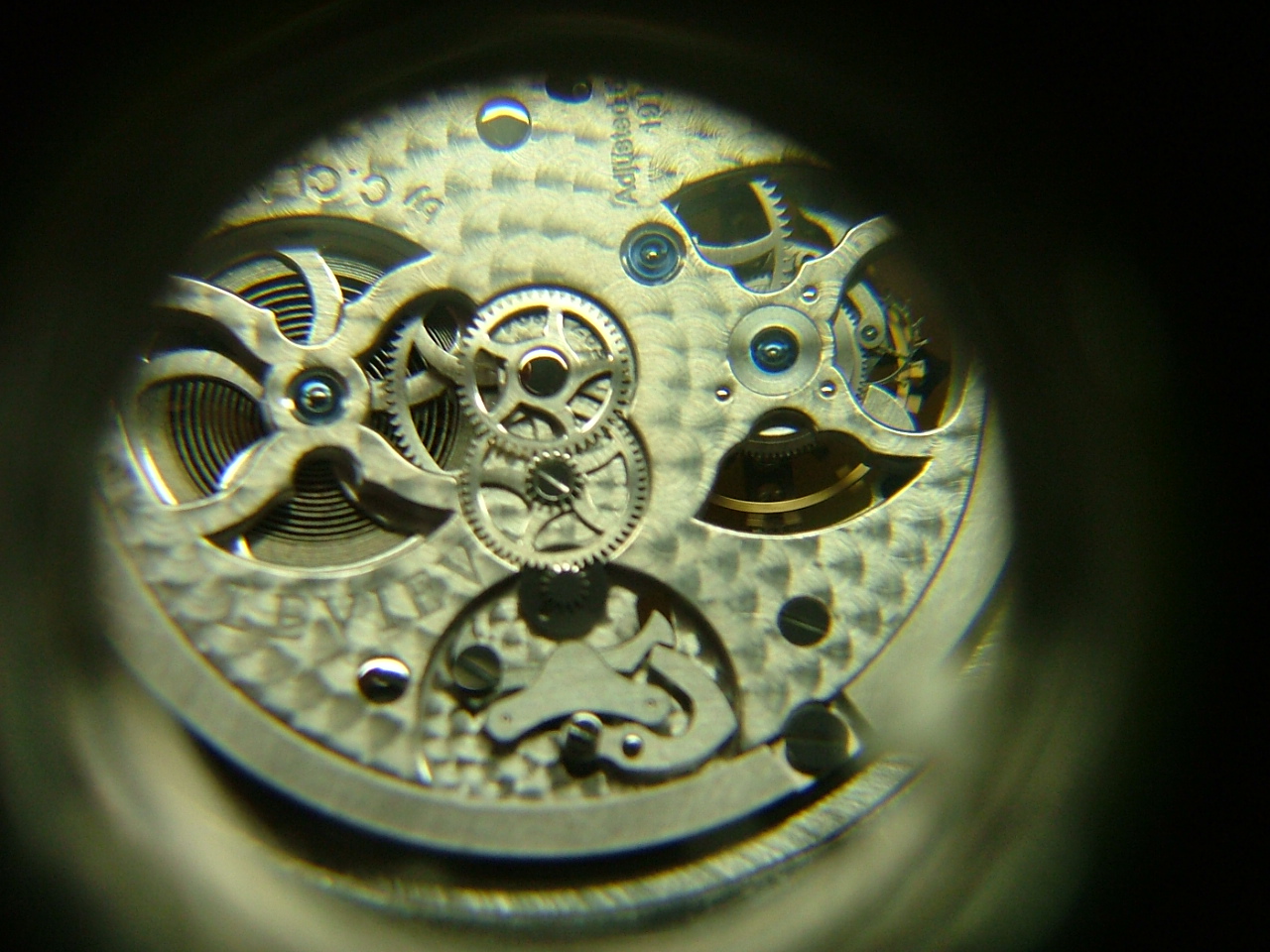

Here we have another Christophe Claret Tourbillon in for service. This particular one had to be disassembled down to the plates due to many problems that were deep down into the movement. It seems the timepiece had some winding problems reported by the customer of this $250,000 piece. This piece was one of the first issued of the limited edition run so it has certainly seen everyday wear and tear over the years. I actually like when I see a timepiece this rare come in and the owner wears it like a beater. This movement can certainly take anything you can throw at it.

I found the winding problem in a very rare place. One of the rivets that are set into the main plates had brought forth a few thousands of a millimeter of play under tension of a rocking setting piece. When the piece had a certain amount of tension applied, the clearance between the rivet head underside and the top of the setting intermediate clutch gear would bind on occasion. I used my staking set and re set the height relationship of the rivet into its proper place after stripping the movement to the plate.

Next up was the Tourbillon cage. The entire cage needed a strip down, cleaning and hand oiling. Of course the pallet stones were checked and adjusted under the fiber optic microscope upon re build for depth, lock and glide. This is a very tedious thing to do. The Tourbillon cage is extremely delicate and would barely register a weight at all on a digital scale, if measured. Its balance and harmony of pieces working in unison takes careful hands to place back to its once brand new condition of perfection.

In addition I did an ultrasonic cleaning of the rest of the movement and hand oiling of all necessary pinions. As there are only myself and Claret in Switzerland who are able to disassemble this piece with proper execution this wonderful Tourbillon made its journey from Dubai to my bench for service along with a few other pieces.

The owner had also a note regarding rundown of the piece being shorter than the 100 hours it should be. I addressed this and found an imbalance in the skeletal pieces, both surrounding the barrel and the barrel itself. The mainspring arbor once back in place with the proper clearance brought us right back to where it should be at 97.2 hours when going through its two week testing procedure after casing up.

Once again I give you a very rare look of the internal micro mechanisms of one of the finest and most complicated wristwatch’s available to mankind. From the Spitz Watchmakers bench in the USA.

Thrash Metal !